MCH 125

NEW REVOLUTIONARY TOPLESS CONCEPT

The MCH 125 luffing jib crane is a game-changer for congested job sites, offering superior performance, exceptional adaptability, and a strong return on investment. Designed with Potain's cutting-edge technology, this crane sets new standards in efficiency and ease of use.

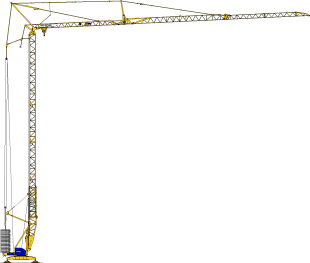

Innovative Luffing Hydraulic System

At the heart of the MCH 125 is its revolutionary VVH Luffing Hydraulic System, which uses an exclusive new hydraulic cylinder to control the jib luffing. This advanced system reduces power consumption compared to conventional luffing mechanisms, allowing for the use of a smaller generator, and significantly lowering operating costs. With the VVH Luffing System, the jib can achieve a full range of motion within just two minutes, maximizing productivity on site.

Fast and Easy Installation

The MCH 125 is engineered for the fastest installation of any luffing jib crane. Many components, including the hydraulic system, hoisting winch, maintenance derrick, and wind side plate, are pre-installed at the factory. This comprehensive pre-assembly eliminates the need for time-consuming on-site adjustments, such as installing luffing wire ropes. The crane also features a unique pre-installed wind-sail configuration that requires no modifications, regardless of jib length. These innovations dramatically reduce setup time and labor costs.

Optimized for Constrained Job Sites

The MCH 125 excels in confined spaces with its ability to raise the jib to a near-vertical position, providing an impressive 87° luffing capacity. The crane’s compact design features a short 7-meter counter-jib and a minimal out-of-service weathervaning radius of 13.5 meters, making it ideal for congested urban environments. Additionally, the cab can be installed on either side of the crane, allowing it to be positioned closer to buildings and other structures.

Cost-Effective Transport and Investment

Transportation of the MCH 125 is streamlined, with the entire upper assembly requiring only four containers or trucks. The compact dimensions of the counter-jib and jib foot enhance transportability, reducing logistics costs. This crane is compatible with standard 1.6-meter or 2-meter L-mast systems, optimizing fleet management and offering the best return on investment for urban construction projects.

Docmentation

MCH 125

SPECIFICATIONS

The fastest installation for a luffing jib crane

- The MCH 125 erects faster and more easily than a luffing crane ever has before

- Hydraulic system components are connected at the factory for faster and easier erection

- No luffing wire rope installation needed thanks to the innovative hydraulic system

- Hoisting winch maintenance derrick and the jib wind side plate are also pre-installed

- Unique wind-sail configuration pre-installed at the factory with no need to adapt onsite for any jib length

Ideal for the most constrained jobsites

- Jib can be raised up to near vertical position: 87° angle luffing capacity

- Very short 7 m Counter jib with simple fixed counterweight installation

- Very short 7 m Counter jib with simple fixed counterweight installation

- Cab can be installed either on the right or the left side of the crane allowing the crane to position close to a building

- LVF: Frequency Variation Lifting mechanisms with 2 hoisting winch options > 40 LVF 20 / 60 LVFC 20 Optima

- Max hoisting speed 81 m/min with 2t for 40 LVF 20

- Max hoisting speed 120 m/min with 1t for 60LVFC 20 Optima

- Drum spooling capacity 456 m 553 m

- RVFC 152 Optima + Slewing mechanism with speeds up to 0.8 rpm

- RVF 152 Optima + Slewing mechanism with speeds up to 0.8 rpm

Best return on investment

- Most adaptable luffing jib crane for congested urban job sites

- Time saving for erecting and dismantling the crane

- Optimized transport for easy and cost-effective logistics

- Standard 1.6 m or 2 m L-mast systems for fleet optimization

Most optimized transport available

- Four containers or four trucks needed for the complete upper slewing crane part

- Compact dimensions of the counter-jib and jib foot also maximize transportability and reduce costs

MANITOWOC GLOBAL SITE

MANITOWOC GLOBAL SITE MCH125-Data-Sheet-Metric-FEM | pdf | Data Sheet

|4.55 MB

MCH125-Data-Sheet-Metric-FEM | pdf | Data Sheet

|4.55 MB