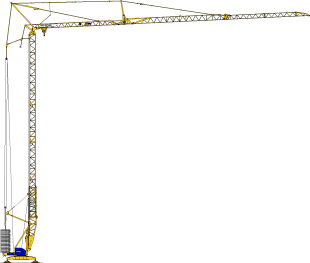

MCH 125A

NEW REVOLUTIONARY TOPLESS CONCEPT

Potain Center of Excellence expertise for the best crane performance. VVH Luffing Hydraulic System. The jib luffing is generated by an exclusive hydraulic cylinder. Power consumption is lower than conventional luffing mechanism as it requires lesser power than competitive models to lower your operating costs. Out-of-service radius of MCH 125A can be as small as 9.3 m (30.5 ft).

Docmentation

MCH 125A

SPECIFICATIONS

The fastest installation for a luffing jib crane

- The MCH 125A erects faster and more easily than a luffing crane ever has before

- Hydraulic system components are connected at the factory for faster and easier erection

- No luffing wire rope installation needed thanks to the innovative hydraulic system

- Hoisting winch maintenance derrick and the jib wind side plate are also pre-installed

- Unique wind-sail configuration pre-installed at the factory with no need to adapt onsite for any jib length

Ideal for the most constrained jobsites

- Jib can be raised up to near vertical position: 87° angle luffing capacity

- Very short 7 m Counter jib with simple fixed counterweight installation

- Very short out-of-service weathervaning radius of 9.3 m is ideal for congested job sites

- Cab can be installed either on the right or the left side of the crane allowing the crane to position close to a building

- LVF: Frequency Variation Lifting mechanisms with 2 hoisting winch options > 40 LVF 20 / 60 LVFC 20 Optima

- Max hoisting speed 81 m/min with 2t for 40 LVF 20

- Max hoisting speed 120 m/min with 1t for 60 LVFC 20 Optima

- Drum spooling capacity 456 m 553 m

- RVFC 152 Optima + Slewing mechanism with speeds up to 0.8 rpm

- RVF 152 Optima + Slewing mechanism with speeds up to 0.8 rpm

Best return on investment

- Most adaptable luffing jib crane for congested urban job sites

- Time saving for erecting and dismantling the crane

- Optimized transport for easy and cost-effective logistics

- Standard 1.6 m or 2 m L-mast systems for fleet optimization

Most optimized transport available

- Four containers or four trucks needed for the complete upper slewing crane part

- Compact dimensions of the counter-jib and jib foot also maximize transportability and reduce costs

MANITOWOC GLOBAL SITE

MANITOWOC GLOBAL SITE MCH 125A | pdf | Data Sheet

|4.54 MB

MCH 125A | pdf | Data Sheet

|4.54 MB